A direct cost is a price that can be directly tied to the production of specific goods or services. A direct cost can be traced to the cost object, which can be a service, product, or department. Direct and indirect costs are the two major types of expenses or costs that companies can incur. Direct costs are often variable costs, meaning they fluctuate with production levels such as inventory. However, some costs, such as indirect costs are more difficult to assign to a specific product. Examples of indirect costs include depreciation and administrative expenses. Show

1:15 Direct CostUnderstanding Direct CostsAlthough direct costs are typically variable costs, they can also include fixed costs. Rent for a factory, for example, could be tied directly to the production facility. Typically, rent would be considered overhead. However, companies can sometimes tie fixed costs to the units produced in a particular facility. Direct Costs ExamplesAny cost that's involved in producing a good, even if it's only a portion of the cost that's allocated to the production facility, are included as direct costs. Some examples of direct costs are listed below:

Because direct costs can be specifically traced to a product, direct costs do not need to be allocated to a product, department, or other cost objects. Direct costs usually benefit only one cost object. Items that are not direct costs are pooled and allocated based on cost drivers. Direct and indirect costs are the major costs involved in the production of a good or service. While direct costs are easily traced to a product, indirect costs are not. Key Takeaways

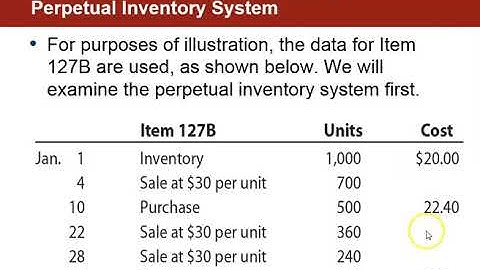

Direct vs. Indirect CostsDirect costs are fairly straightforward in determining their cost object. For example, Ford Motor Company (F) manufactures automobiles and trucks. The steel and bolts needed for the production of a car or truck would be classified as direct costs. However, an indirect cost would be the electricity for the manufacturing plant. Although the electricity expense can be tied to the facility, it can't be directly tied to a specific unit and is, therefore, classified as indirect. Fixed vs. VariableDirect costs do not need to be fixed in nature, as their unit cost may change over time or depending on the quantity being utilized. An example is the salary of a supervisor that worked on a single project. This cost may be directly attributed to the project and relates to a fixed dollar amount. Materials that were used to build the product, such as wood or gasoline, might be directly traced but do not contain a fixed dollar amount. This is because the quantity of the supervisor's salary is known, while the unit production levels are variable based upon sales. Inventory Valuation MeasurementUsing direct costs requires strict management of inventory valuation when inventory is purchased at different dollar amounts. For example, the cost of an essential component of an item being manufactured may change over time. As the item is being manufactured, the component piece's price must be directly traced to the item. For example, in the construction of a building, a company may have purchased a window for $500 and another window for $600. If only one window is to be installed on the building and the other is to remain in inventory, consistent application of accounting valuation must occur. Companies typically trace these costs using two methods: first-in, first-out (FIFO) or last-in, first-out (LIFO). FIFO involves the assigning of costs, such as the purchase of inventory, based on what items arrived first. As inventory is used up in the production of goods, the first ones or the oldest inventory items are used first when measuring the cost of the item. Conversely, LIFO assigns the value of a cost item based on the last item purchased or added to inventory. Rent expense is often a monthly amount paid by a company for use of a building. Typically, the rent is due on the first day of every month that the building is occupied. Definition of a Period CostA period cost is a cost that is used up or expires in the accounting period. As a result, the cost is reported as an expense on the income statement. Definition of a Product CostA product cost is a cost that is either directly or indirectly assigned to the goods that are produced or manufactured by the company. Product costs are the raw materials, labor, and manufacturing overhead used to produce the goods. Think of product costs as clinging to the goods produced. The rent associated with the manufacturing operations is part of manufacturing overhead, which is allocated to the products manufactured. As a result, the allocated manufacturing cost will be included as part of the following costs:

Examples of Rent as a Period ExpenseIf a company's monthly rent is for use of assets involved in its selling function (rent for office space, equipment, autos, etc.) or its administrative function of the company, the rent is a period cost and will be expensed in the period when the expense is incurred. These rents are not allocated to products for its external financial statements. Example of Rent as a Product CostIf a manufacturer rents its manufacturing facilities and equipment, the rent is a product cost (as opposed to an expense of the period). That is, the rents will be included in the manufacturing overhead which is allocated to the goods produced. (Think of the manufacturing rents as clinging to the goods produced.) As a result, the manufacturing rents will be part of the products that are in inventory and will be part of the cost of the products sold. When the items in inventory are sold, the manufacturing rent allocated to those products will be expensed as part of the cost of goods sold. What type of cost is factory rent?If a manufacturer rents its manufacturing facilities and equipment, the rent is a product cost (as opposed to an expense of the period). That is, the rents will be included in the manufacturing overhead which is allocated to the goods produced.

Is factory rent an indirect cost?Rent on a factory building is an indirect cost because it is a cost which has been incurred in order to keep the business running as a whole and, so it cannot be directly linked with the cost of a product or service and, hence it is an indirect cost.

Is factory rent a cost of goods sold?Importantly, COGS is based only on the costs that are directly utilized in producing that revenue, such as the company's inventory or labor costs that can be attributed to specific sales. By contrast, fixed costs such as managerial salaries, rent, and utilities are not included in COGS.

Is factory rent included in manufacturing overhead?The rental cost of a building used in manufacturing is part of manufacturing overhead. Manufacturing overhead is assigned or allocated to the units produced. As a result, the units produced include part of the rent of the manufacturing building.

|